As an engineer, understanding the different types of engine starting methods is crucial for ensuring that your industrial engines start up quickly and efficiently. While there are various starting methods available, the purpose of this article is to compare hydraulic starting and spring starting. In this article, we’ll examine the key differences between these two methods, their applications, benefits, and limitations.

Hydraulic Engine Starting

Hydraulic engine starting is primarily used in the marine, oil and gas, mining, and construction industries, among others. The method is used to start diesel or propulsion engines, and it relies on liquid power. Hydraulic starters can be used to start engines of up to 80 litres capacity, making them ideal for larger industrial engines.

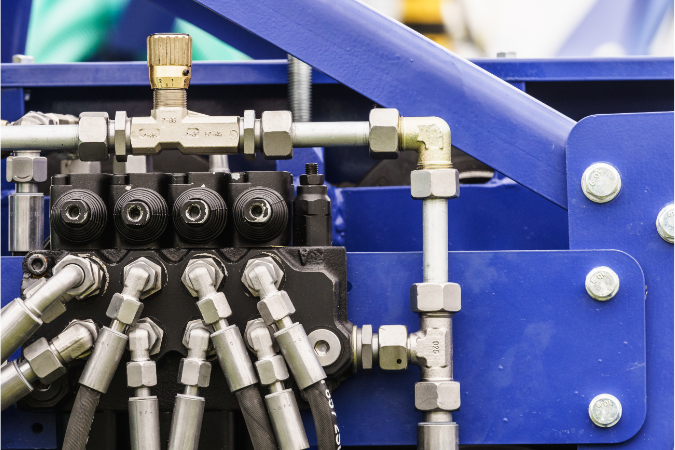

The hydraulic starting method works by using a hydraulic pump to force hydraulic fluid towards a piston type starter motor, which engages the starter motor pinion with the ring gear of the fly wheel to then start the engine. The hydraulic starting method is reliable, quick, and energy efficient, making it an excellent choice for high-powered engines.

Spring Starting

Spring starting is prevalent in lifeboats and marine applications where alternative sources of backup energy are necessary in case of a power failure. If you need an alternative way to start an engine, and you can't use hydraulic power or compressed air, spring starting is a good alternative.

A spring starter device releases kinetic energy to start the engine, using the stored mechanical energy in a spring to engage the engine's starting system. Hatraco now owns the business that produces most of the world’s best quality spring starters, which can be used not only on gas engines, but on diesel engines as well. Spring starters are best suited to smaller engines up to 15 litres in capacity. The main benefit is that they require no external energy source and are considered the most reliable form of engine starting.

How To Make The Right Choice For Your Application

Hydraulic and spring starting methods each provide benefits in certain circumstances, and determining which option to select depends on various factors. In general, hydraulic starting is more suitable for larger engines and applications that require frequent use but can be costly and complex to maintain.

In comparison, spring starting is ideal for smaller engines and applications where an external power source isn't readily available.

Factors that determine which starting method to use include the type of engine, application, cost, and maintenance requirements. An engine that has a hydraulic pump already installed may be best served with hydraulic engine starting. However, if the engine is smaller, portable, or used infrequently, spring starting may be a more suitable option.

Cost Comparison

In terms of cost, hydraulic engine starting equipment is more expensive to install than spring starting, as it requires a hydraulic pump, line, and hydraulic motor. Spring starting simply requires a manual winding mechanism for the spring, which could be less costly depending on the application.

Servicing And Maintenance

Another consideration is maintenance requirements. Hydraulic power can be subject to contamination from debris, which could cause damage to the hydraulic motors, pumps and lines, leading to costly repairs. Spring starters, on the other hand, require minimal maintenance, as the energy source is mechanical, requiring only lubrication and regular inspection.

Find Out More

To find out more about our range of components for industrial engines, please get in touch with R&M Walsh Ltd today.

Image Source: Canva

Apply for an Account

Apply for an Account Log In

Log In 0Basket

0Basket Checkout

Checkout

01782 983376

01782 983376 info@rmwalshltd.co.uk

info@rmwalshltd.co.uk